Copyright 2011 JINAN HAOYU CNC MACHINERY CO., LTD All Rights Reserved.

Longitudinal Seam Butt Automatic Welding Machine

basic information

Categories:

Product

Longitudinal Seam Butt Automatic Welding Machine

I.Welding Requirements:

- To finish the flat metal sheet butt joint welding automatically.

- To guarantee the uniform surface forming and good appearance, the depth of fusion and width of fusing reach the welding requirement.

- It is easy to clamp and load. Adopts butt welding process, it requires one side welding both sides formation.

II.Equipment Features

- Welding torch moves longitudinally. Air cylinder presses the workpiece with high positioning accuracy. Welding position is horizontal.

- MIG automatic welding type.

- The welding torch can be adjusted longitudinally,to meet various welding type.

- PLC control the whole machine operation, stepless adjustment,to improve the stability of machine.

- The welding mode and welding specification can be preset, saved and recalled.It is convenient to modify the parameter and switch the status through the man-machine touch screen.

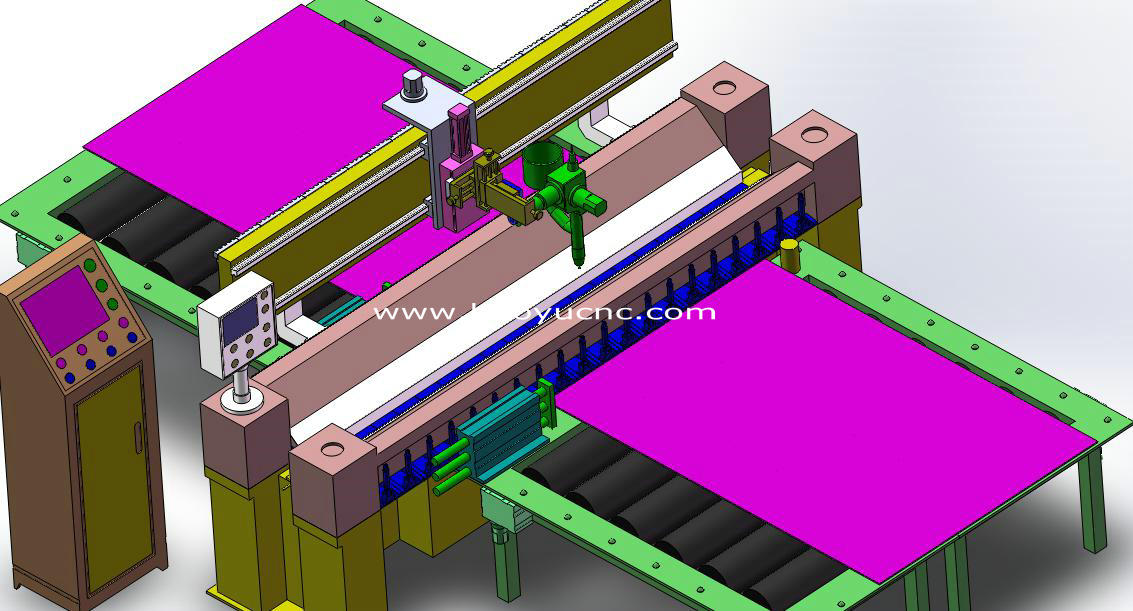

III.Equipment Layout

IV.Equipment Composition

The machine is made up of gantry type working table, welding torch longitudinal moving mechanism, pneumatic clamping bar mechanism, loading and unloading table, fixture, conductivity mechanism, welding torch lifting,clamping and adjusting mechanism, electrical control system, welding power source and pneumatic system.

V.Working Process

manual loading → positioning plate lifts,after the two ends of the workpiece are correctly positioned→ Welding torch falls automatically → welding torch starts to weld → reach at the given length → small current,low voltage for arc igniting →return welding torch and release workpiece → automatic unloading

VI.Technical Parameters

|

Motor power |

0.75KW |

|

Welding torch adjusting volume |

up and down:100mm |

|

|

left and right: 100mm |

|

|

tilting angle:25°- 60° |

|

Welding current |

50-500A,60% duty cycle |

|

Wire diameter |

1.0mm and Φ1.2mm |

|

Argon gas consumption |

15L/MIN |

|

Working voltage |

380V±15%,3ph, 50hz |

|

Workpiece dimension |

2000*3000mm |

The next article

Automatic Welding Machine for Hard Facing Roller Build Up